- Home Page

- Company Profile

-

Our Products

- AC and DC Motors

- Gear Motors

- Gear Electric Motor

- Gear Motor

- Flange Motor

- Fhp Vertical Gear Motor

- Fhp Gear Motor

- FHP Vertical Gear Motor

- FHP Gear Motor

- Worm Geared Motor

- Cooling Tower Motor

- Brake Motor

- Three Stage Helical AC Geared Motor

- Ac Gear Motors

- Universal Worm Reducer Gear Motor

- Ac Gear Motor

- Warm Gear Motor

- Universal Worm Reducer

- Universal Warm Reducer Gear Motor

- Vibratory Motor

- Vibration Motors

- Vibrating Motors for Concrete Vibrating Table

- Vibrating Motor

- Unbalanced Vibration Motors

- Foot Mounted Vibratory Motors

- Rotary Vibratory Motors

- Flange Mounted Vibratory Motors

- Flange Vibratory Motor

- Mounted Vibratory Motor

- Foot Mounted Vibratory Motor

- Flange Mounted Vibratory Motor

- Electric Vibratory Motors

- Vertical Flange Mounted Vibratory Motor

- Vibratory Motor Flange Mounted

- Vertical Flange Mounted Vibrator Motor

- AC Servo Motors and Drives

- Helical Gear Motor

- Air Blower Motors

- Electric Motors

- Torque Motor

- Ci Triplex Gear Pumps

- Stainless Steel Rotary Gear Pump

- Twin Lobe Roots Blower

- Gear Motor Helical Gear Motor

- Bench Grinders and Polishers

- Three Phase Electric Motor 220kW ABB Make

- Single Phase Motor

- Electric Motor Drives

- Industrial Coolant Pump

- Coolant Pumps

- Motor Drives

- Polisher Motor

- Die Cast Motors

- Loom Motors

- Gear Boxes

- Contact Us

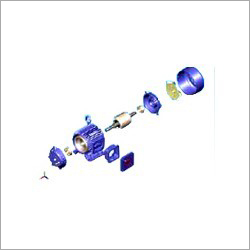

Die Cast Motors

Product Details:

- Voltage 220V / 415V

- Pressure Standard

- Cooling Method Air Cooled

- Standard IS 325 / IEC 60034

- Torque Variable depending on rating

- Noise Level <65 dB

- Power Rating 0.18 kW to 3.7 kW

- Click to View more

X

Die Cast Motors Product Specifications

- Foot Mounted / Flange Mounted

- -15C to 50C

- IP55

- 2 / 4

- IE2/IE3

- Grey

- 220V/415V

- 7 Kg to 40 Kg

- High efficiency, compact design, long life, low maintenance, smooth operation

- 1440 RPM

- Single Phase / Three Phase

- 50 Hz

- Double Shielded Ball Bearing

- 180W to 3750W

- Totally Enclosed

- Direct-On-Line (DOL)

- Totally Enclosed

- Die Cast Induction Motor

- AC

- AC Induction Motor

- 50 Hz

- 220V / 415V

- Variable depending on rating

- IS 325 / IEC 60034

- Air Cooled

- Standard

- 0.25 HP to 5 HP

- 0.25 HP to 5 HP

- 0.18 kW to 3.7 kW

- <65 dB

- Standard as per requirement

- Standard as per IS

Product Description

Die cast motors is electric motors that are manufactured using the die casting process, a manufacturing technique that involves injecting molten metal under high pressure into a mold or die to create a specific shape or part. Die casting is a popular method for manufacturing small to medium-sized parts in large quantities, and it offers several advantages over other manufacturing processes.Designed for Demanding Industrial Operations

Our Die Cast Motors are built to withstand continuous (S1) operation in tough industrial settings. The combination of a totally enclosed die cast aluminum housing and an IP55 protection rating shields the motor from dust and moisture, ensuring consistent performance in harsh environments. These motors are ideal for heavy-duty applications such as driving pumps, compressors, and conveyors.

High Efficiency and Low Maintenance

Engineered for high efficiency (IE2/IE3) and smooth operation, these motors deliver optimal energy savings while minimizing noise and vibration. The use of double shielded ball bearings and air cooling extends operational life and reduces maintenance requirements. Their compact and durable design makes them both reliable and easy to install in various setups.

FAQ's of Die Cast Motors:

Q: How do Die Cast Motors enhance industrial machinery performance?

A: Die Cast Motors improve industrial machinery by offering high efficiency (IE2/IE3), reliable insulation (Class F), and a robust die cast aluminum enclosure that ensures consistent, long-lasting operation even under continuous load (S1 Duty). This makes them excellent for pumps, blowers, fans, and conveyors.Q: What is the process for installing these Die Cast Induction Motors?

A: These motors can be installed using either foot-mounted or flange-mounted configurations, as per standard requirements. Wiring supports both star/delta connections and DOL (Direct-On-Line) starting, making setup straightforward for single phase or three phase systems.Q: When should I choose a motor with a squirrel cage rotor?

A: A squirrel cage rotor is ideal when you require low maintenance, robust construction, and reliable performance in standard industrial applications, such as continuous duty operations in pumps or conveyors.Q: Where can these motors be used safely?

A: The motors are designed for use in industrial environments exposed to dust or moisture thanks to their IP55 rating and totally enclosed construction. They are suitable for a wide range of installations, including manufacturing plants, water treatment facilities, and HVAC systems.Q: What benefits do these motors offer over conventional models?

A: These motors feature a compact, lightweight, and powder-coated design that resists corrosion. Their high efficiency, smooth and quiet operation (<65 dB), and long service life provide operational cost savings and reduced downtime compared to conventional motors.Q: How does the service factor of 1.15 affect motor operation?

A: A service factor of 1.15 means the motor can handle up to 15% overload without affecting its operational life, providing extra reliability for handling variable loads commonly found in industrial processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email